|

Product renewal, moving forward towards a new direction!December 27th As the 96th anniversary of its establishment approaches Wuling Willow Machine Embark on a new journey, 'Ling Shi' moves forward New energy integrated electric drive workshop unveiled and put into use The new generation of efficient hybrid assembly is put into production and offline 3 new energy products officially released

Born from the 'new', creating a new future of electric drive

Faced with the technological development trend of high efficiency, multi electrification, and intelligence in hybrid power systems, Wuling Liuji focuses precisely on customer hybrid integration application scenarios, relying on the integration technology of gasoline engine and motor coupling, and building a new energy integrated electric drive workshop on the basis of the advantages of engine motor motor controller system hybrid power development and manufacturing. It has added 100000 sets of hybrid and pure electric drive system production capacity per year, and entered a new stage of new energy layout. Riding on the 'new' and shaping new advantages for development

Wuling Liuji adheres to the dual engine drive of "engine technology upgrade, new energy integration application", and is committed to providing more efficient and energy-saving system solutions for vehicle customers, promoting transformation and upgrading through technological innovation. The new generation efficient hybrid assembly integrating multiple advanced technologies has been put into production, marking significant achievements in strengthening technological innovation and focusing on green development. It is another milestone in the company's development of new quality productivity and innovative hybrid technology. Moving towards the 'new' and building a strong new engine

Adhering to the corporate spirit of "hard work and self-improvement", Wuling Liuji inherits and accumulates, innovates and seeks change, continuously accelerates the landing of new products, and continuously improves the product matrix. On the occasion of entering the "centenary", three new energy products have been officially released, including a new generation of high-efficiency hybrid assemblies, a new generation of longitudinal DHT, and a multi in one electric drive system, as a gift for the 96th anniversary of the factory's establishment. New generation efficient hybrid assembly

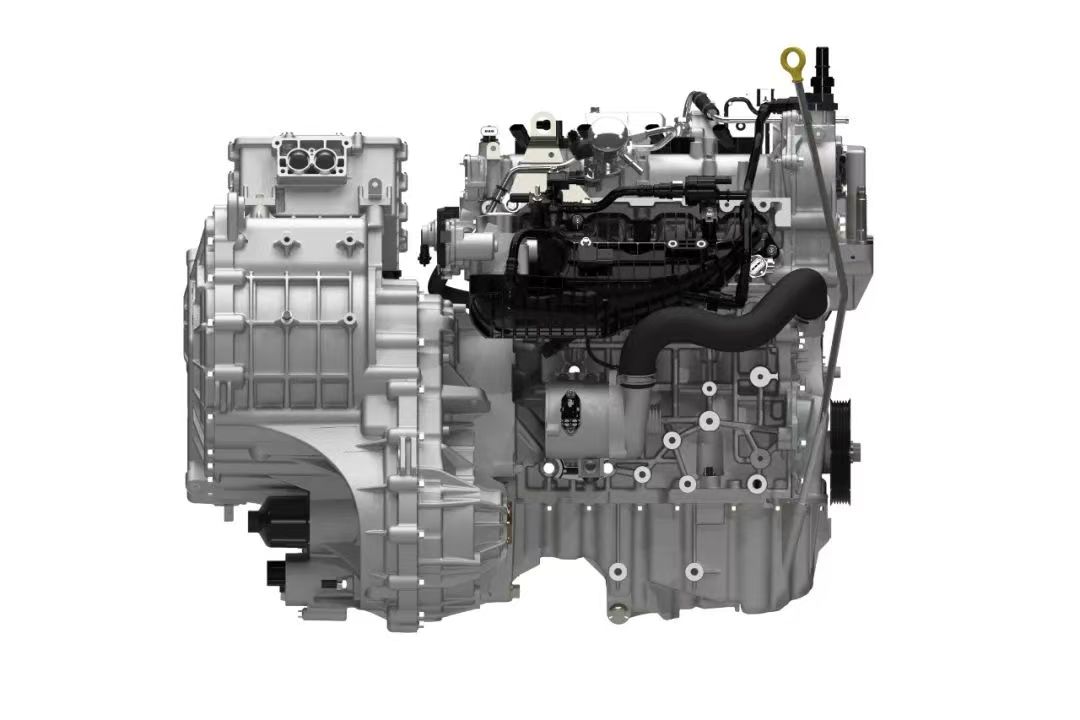

By ingeniously integrating the third-generation H15T high-efficiency hybrid engine and the fifth generation DHT hybrid transmission technology, the axial size is further reduced and the weight is reduced by 15%. The system efficiency is as high as 93%, leading the industry. It can be widely adapted to SUV, MPV and other passenger cars, perfectly integrating high efficiency, energy saving and practical convenience, reshaping the driving experience. New generation vertical DHT

Accurately focusing on the application scenarios of longitudinal front wheel drive for the whole vehicle, adopting an eccentric parallel axis motor layout, taking into account both axial and radial dimensions, highly integrated motor, electronic control, and reducer, as the longitudinal front wheel drive power, suitable for four-wheel drive/two wheel drive models, can flexibly switch between main drive and auxiliary drive according to the power requirements of the whole vehicle, meet different driving conditions, and have a good driving experience. Multi in one electric drive system

Adopting oil cooled flat wire motor technology, the highest efficiency is greater than 97%. The product meets the EMC requirements of Class 3 and is deeply integrated. It has the advantages of high stiffness, small size, light weight, compact structure, and high power density. It has been widely used in multiple pure electric vehicle projects. |